1J22磁性能及其应用

1J22是高饱和磁感应强度铁钴钒软磁合金,是现有的软磁合金中饱和磁感应强度最高的,可达2.4T, 在制作同等功率的电机时,可大大缩小体积,在作电磁铁时,在同样的截面积下能产生最大的吸合力。

1J22铁钴钒合金的居里点也很高,达到980℃,可以使该铁钴钒合金能在其他软磁材料已经完全退磁的较高温度下工作,并保持良好的磁稳定性。

由于1J22有大的磁致伸缩系数,最大达到60~100x10-6,非常适于制作磁致伸缩换能器,输出能量高,工作效率也高。

1J22的化学成分

|

C |

Mn |

Si |

P |

S |

Cu |

Ni |

Co |

V |

Fe |

|

≤0.04 |

≤0.30 |

≤0.30 |

≤0.020 |

≤0.020 |

≤0.20 |

≤0.50 |

49.0-51.0 |

0.80-1.80 |

余量 |

1J22铁钴钒合金在不同厚度的典型静态磁性能见下表:

|

δ/mm |

在不同磁场强度(A/m)下的静态磁性能/T |

Hc/(A/m)≤ |

|||||

|

B400 |

B800 |

B1600 |

B2400 |

B4000 |

B8000 |

||

|

0.1 |

1.68~1.79 |

1.94~2.01 |

2.12~2.15 |

2.20~2.25 |

2.28~2.31 |

2.35~2.40 |

120~148 |

|

0.2 |

1.70~1.80 |

2.00~2.02 |

2.15~2.18 |

2.22~2.25 |

2.30~2.33 |

2.40~2.41 |

115~135 |

|

0.35 |

1.70~1.81 |

1.95~2.02 |

2.12~2.17 |

2.20~2.24 |

2.20~2.24 |

2.28~2.34 |

123~135 |

1J22铁钴钒合金在不同厚度时的铁损见下表

|

δ/mm |

f/Hz |

P/(W/kg) |

||||

|

P1.5 |

P1.7 |

P1.9 |

P2.0 |

P2.1 |

||

|

0.1 |

50 |

3.54~4.74 |

4.40~5.93 |

5.49~7.52 |

6.32~9.05 |

8.29~11.8 |

|

400 |

30.15~39 |

31.5~48.6 |

42.5~58.4 |

48.7~63.2 |

55.5~69.4 |

|

|

800 |

62.7~82.4 |

78.3~102.1 |

94.5~122.5 |

103~131.5 |

114.1~153.1 |

|

|

1000 |

74.6~105.9 |

91.7~132 |

110.9~158.3 |

122~173.1 |

138.8~197.8 |

|

|

0.2 |

50 |

3.68~4.03 |

4.59~4.99 |

5.77~6.62 |

6.7~7.87 |

8.33~9.84 |

|

400 |

35.2~36.3 |

43.7~45.2 |

50.4~56.5 |

58.4~64.2 |

64.0~77.6 |

|

|

800 |

84.7~87.7 |

106.5~110.8 |

130.6~138.2 |

144~156.1 |

157.0~179 |

|

|

1000 |

115.2~121.4 |

146~153.1 |

182~192.3 |

198~210.8 |

222~241 |

|

|

0.35 |

50 |

3.79~4.19 |

4.66~5.30 |

5.48~6.95 |

6.29~9.27 |

7.00~9.75 |

|

400 |

45.1~51.3 |

56.9~65.1 |

70.2~79.6 |

77.5~88.4 |

85.7~99.8 |

|

|

800 |

125.1~145 |

161.1~188 |

204~233 |

227~258 |

241~290.5 |

|

|

1000 |

177.5~206 |

234~266 |

297~334 |

332~374 |

369.5~434 |

|

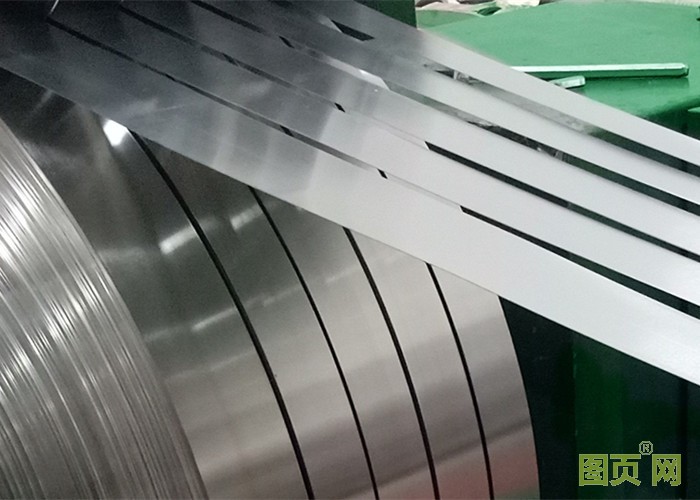

1J22铁钴钒合金的品种规格与供应状态

以冷轧带材、冷拉丝材,热轧(锻)扁材和棒材,不经热处理供应。品种规格、尺寸及允许偏差见下表

|

产品种类 |

(δ或D)/mm |

B/mm |

L/mm≥ |

产品种类 |

(δ或D)/mm |

B/mm |

L/mm≥ |

||

|

尺寸 |

允许偏差 |

尺寸 |

允许偏差 |

||||||

|

冷轧带材 |

0.05~0.09 |

0 -0.015 |

60~120 |

5000 |

冷拉丝材 |

>0.49~0.09 |

±0.03 |

- |

- |

|

>0.09~0.19 |

0 -0.02 |

500 |

>0.90~3.00 |

±0.04 |

|||||

|

>0.19~0.25 |

0 -0.03 |

200 |

>3.00~6.00 |

±0.06 |

|||||

|

>0.25~0.40 |

0 -0.04 |

200 |

热轧(锻)扁材和棒材 |

6.0~8.0 |

±0.5 |

- |

1000 |

||

|

>0.40~0.70 |

0 -0.05 |

200 |

>8.0~12.0 |

±1.0 |

1000 |

||||

|

>0.70~1.00 |

0 -0.06 |

200 |

>12.0~35.0 |

±1.5 |

250 |

||||

|

冷拉丝材 |

0.10~0.19 |

±0.01 |

- |

- |

>35.0~50.0 |

±2.0 |

250 |

||

|

>0.19~0.49 |

±0.02 |

>50.0~80.0 |

±4.0 |

250 |

|||||

|

>80.0~100.0 |

±5.0 |

150 |

|||||||

1J22铁钴钒软磁合金已生产、使用多年,性能稳定,材料较成熟。适宜做质量轻、体积小的航空、航天用电器元件,如微电子转子、电磁铁极头、继电器、换能器等。